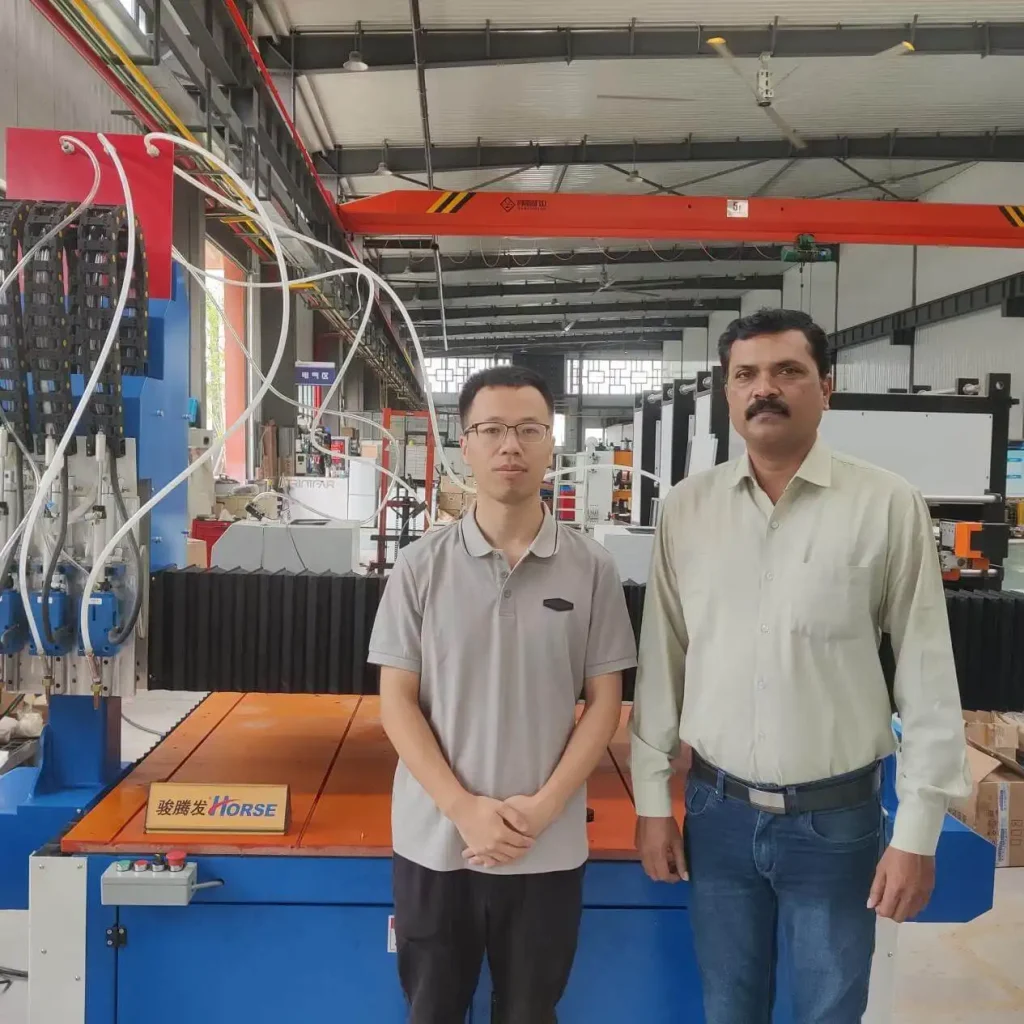

In collaboration with a leading brand and Mumbai’s largest electrical...

Auto Parts/ Home Appliance Parts/ New Energy Accessories Laser Workstation

Laser welding robots are efficient, stable, highly automated, and have good compatibility. They offer low processing costs per unit. Laser welding is a non-contact welding process, which does not require pressure during operation. The working principle involves directing a high-energy laser beam onto the material’s surface. Through the interaction between the laser and the material, the material melts internally, then cools and crystallizes to form the weld seam. This process is suitable for various types of mass production and can be equipped with options such as rotating tables and positioners to complete the production and processing of different workpieces. Its flexible application represents a new force and trend for modern industrial development.

Product Details

Laser welding robots are efficient, stable, highly automated, and have good compatibility. They offer low processing costs per unit. Laser welding is a non-contact welding process, which does not require pressure during operation. The working principle involves directing a high-energy laser beam onto the material’s surface. Through the interaction between the laser and the material, the material melts internally, then cools and crystallizes to form the weld seam. This process is suitable for various types of mass production and can be equipped with options such as rotating tables and positioners to complete the production and processing of different workpieces. Its flexible application represents a new force and trend for modern industrial development.

Short Circuit Current

200W~6000W

Industry Applications

Applicable industries: home appliances, automotive parts, water pumps, doors and windows, distribution boxes, electronics, automotive accessories, computer and TV housings, stainless steel products, aluminum alloy products, zinc alloy products, aerospace and aviation industries, etc.

Product Advantage:

- Adopt the New Generation of Fiber Laser Machines

- Simple Operation, Beautiful Welds, Fast Welding Speed, No Consumables

- Suitable for Welding Thin Stainless Steel, Iron Plates, Galvanized Plates, and Other Metals, Replacing TIG Welding

- No Deformation, No Consumables, Easy Operation, Beautiful Weld Seams!

- Six-Axis Linkage, Capable of Completing Arbitrary Trajectories in Space. The Robotic Arm and Fiber Laser Welding Machine Are Perfectly Integrated to Meet the Needs of Various Flexible Automation Production.

- Adjustable Multi-Angle Welding, Flexible and Convenient, Easy to Install Fixtures and Position Workpieces.

- Strong Equipment Reliability, Capable of Continuous and Stable Operation for 24 Hours, Meeting the Demands of Large-Scale Industrial Production.

- Strong Customization Ability, Capable of Tailoring Machines According to Customer Needs.

- Multiple Position Welding, Saving Time and Effort!

Related Products

Related products

FAQ

Are you a trading company or a factory?

We are an integrated industry and trade company, and we have our own factory.

Where is your factory located?

Our factory is located in the Songjiang district of Shanghai, China. Additionally, we have factories in Dongguan and Ningbo.

Can you customize the machine?

Yes, we support OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services and can customize machines according to your requirements.

What is the MOQ (Minimum Order Quantity)?

The MOQ depends on the customer’s requirements.

Can you provide samples?

Yes, we provide sampling services. However, you will need to send us the sample by courier.

What services do you provide during the purchase process?

- Pre-sales: Factory visits, technical solutions, program design services, proofing, and sample testing.

- On-sales: Technical training and installation/commissioning services.

- After-sales: Free non-wearable parts, repair services, video technical support, and online remote guidance.

How long is your warranty period?

We offer a one-year warranty.

What are the payment terms?

We usually require full payment before shipping, but payment terms can be negotiated.

How long is the delivery time?

- Standard machines: 7–15 working days.

- Customized machines: Depending on the degree of customization, approximately 1–3 months.

Business Casestudies

For a Russian precision instrument manufacturer, we supplied a dedicated...

Our local authorized distributor in Thailand provides year-round on-site technical...

A leading enterprise in Bangladesh received a complete oven welding...