In collaboration with a leading brand and Mumbai’s largest electrical...

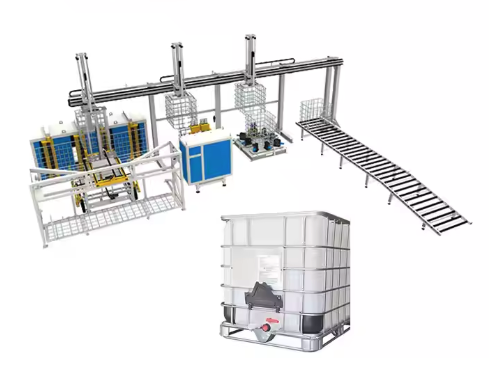

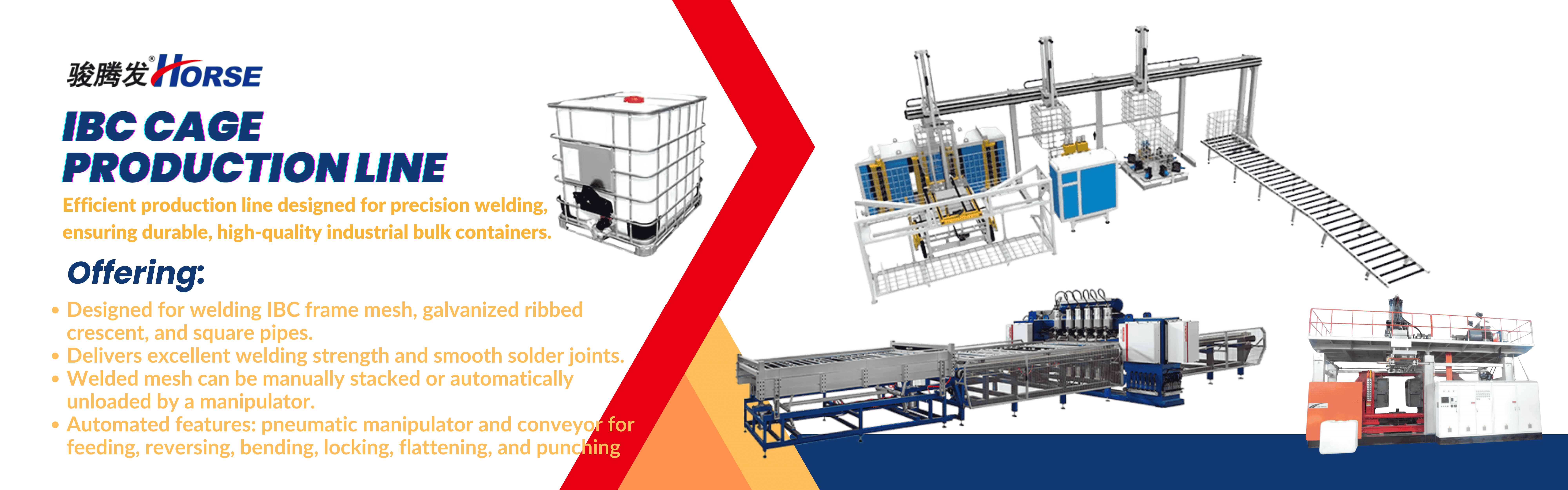

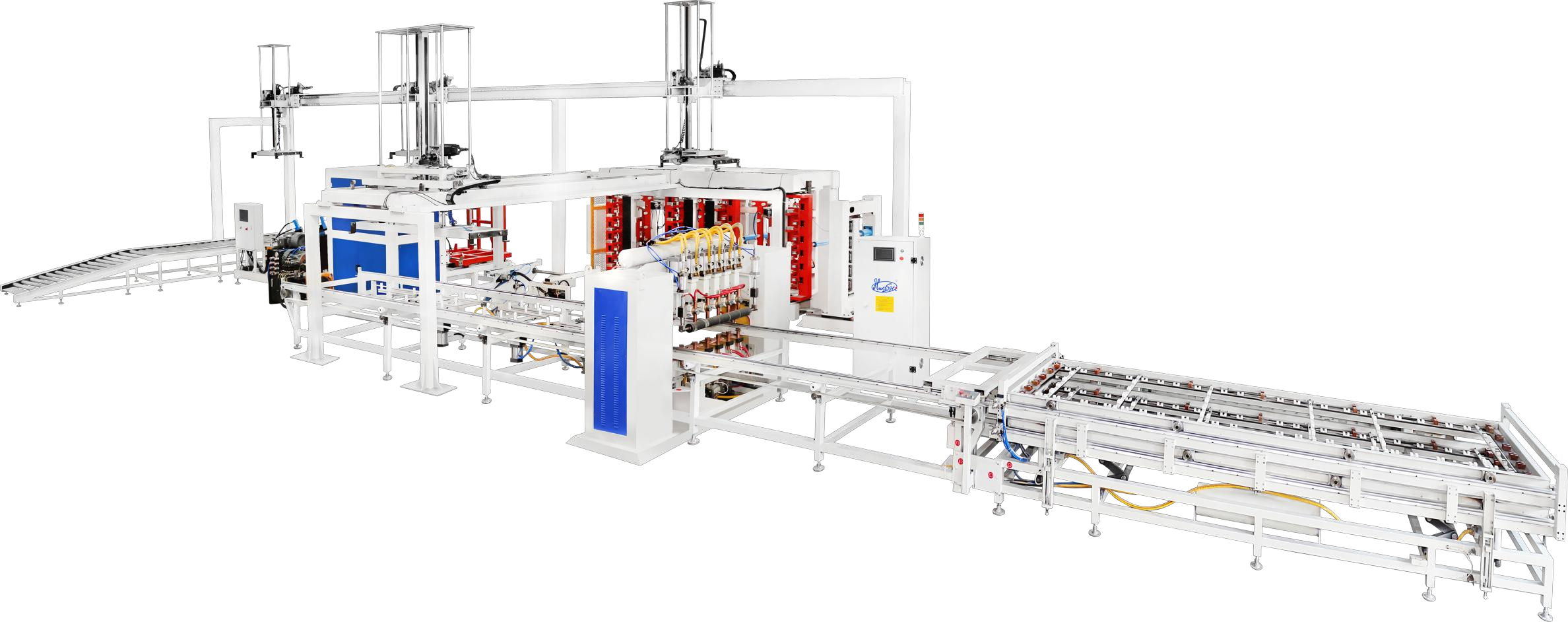

The Trintfar Automatic IBC Tubular Frame Welding Machine is a cutting-edge solution tailored for the efficient and precise welding of IBC tank tubular frames. Designed for high productivity and durability, this machine is the ideal choice for industries requiring consistent performance and minimal maintenance.

For detailed specifications: Click here

Key Features:

- Weight & Build: Robust structure weighing 300 KG, ensuring stability and longevity in industrial environments.

- Advanced Welding Capability: Equipped with 6 welding heads for simultaneous welding, enhancing production speed.

- Stepping Welding Speed: Adjustable speed ranging from 500mm to 1000mm/sec, catering to various frame sizes and requirements.

- Precision Engineering: High-performance metal casting machinery ensures flawless welds every time.

Production Results:

Specifications:

- Automatic Grade: Fully automated for streamlined operations.

- Dimensions: Compact design of 50X50X50 cm, optimized for industrial spaces.

- Voltage & Power: Operates on 380V with a power rating of 100 units, delivering energy-efficient performance.

- Application: Specially designed for IBC tank tubular frame welding to meet industry-specific demands.

Delivery:

- Weight: Durable construction with a total weight of 300 KG, ensuring operational stability.

- Packaging: Delivered in a wooden box for secure and safe transportation.

- Port of Dispatch: Shipped from Shanghai, offering efficient global delivery options.

Additional Support:

- After-Warranty Service: Includes video technical support to assist with troubleshooting and maintenance.

- Place of Origin: Manufactured in Shanghai, China, ensuring top-tier quality standards.

The Trintfar IBC Tubular Frame Welding Machine is a reliable and efficient partner for your production line, combining precision, speed, and durability to meet the evolving demands of the industry.